“Top 10 Screw Air Compressor Manufacturers & Suppliers in Israel.

If you are looking for Screw Air Compressor Manufacturers & Suppliers in Israel, you are on the right place.

We here listed the Top Screw Air Compressor Manufacturers & Suppliers in Israel.

Check and ask for a quote for air compressors, rotary screw air compressors, screw air compressors, industrial air compressors, tank mounted integrated air compressors, centrifugal air compressors, you can send us your requirements. We will quote to you.”

1 Kaeser Compressors ltd

2 Power compressors

Is a company that specializes in compressors for over 40 years We specialize exclusively in compressors and pneumatic tools. We have a professional team that has undergone professional training that provides a fast and reliable professional service to solve any problem in your compressor or air system. Our technicians perform annual treatments for all types of compressors. The recommendations of the compressor manufacturers is to do periodic treatment between 6 months and 12 months. We provide service to the customer’s home. We have a repair lab at 77 Kibbutz Galuyot Street, Tel Aviv. We invite you to be impressed by our site to find products which we import from all kinds of companies in different countries from Italy, United States, Germany, Spain, Taiwan and China. Carpentry compressor, garage compressor, screw compressor, piston compressor, compressor spare parts, painting equipment, airbrush compressor, air dryer for the compressor, electric water dispenser for draining the air tank, Find find with us an available stock of spare parts for all types of different compressors: gaskets, rings, drive belts, electric motors, three-phase persostat, single-phase persoster (electric starter), oil for all types of compressors, connections, filters, water filter and more. .

3 מדחסים

Is a company that specializes in compressors for over 40 years We specialize exclusively in compressors and pneumatic tools. We have a professional team that has undergone professional training that provides a fast and reliable professional service to solve any problem in your compressor or air system. Our technicians perform annual treatments for all types of compressors.

4 אלגרו – תיקון מזגנים

5 מיזוג מהיר

The oil injected rotary screw compressor is a positive displacement type compressor. A given quantity of air or gas is trapped in a compression chamber and the space that it occupies is mechanically reduced, causing a corresponding rise in pressure prior to discharge. A rotary screw compressor has a pair of intermeshing rotors housed in a suitable casing to produce compression.

6 אביאל כהן טכנאי מזגנים

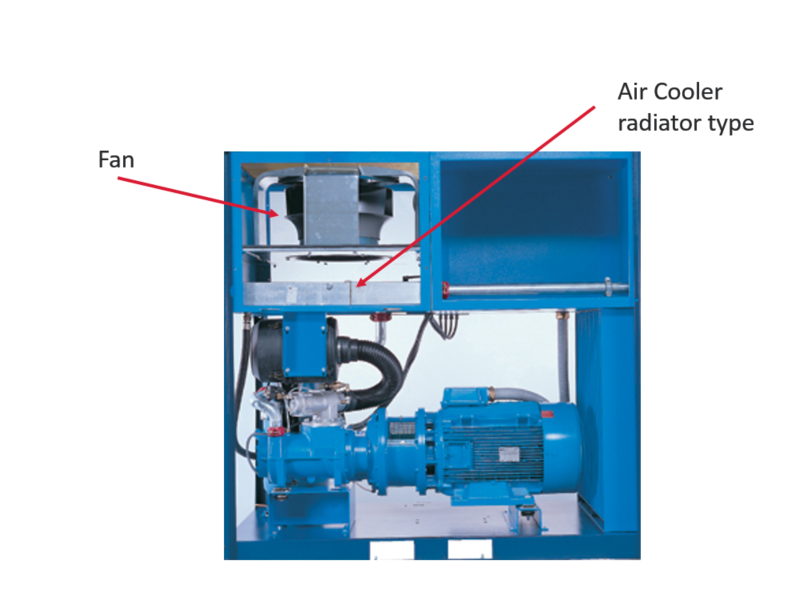

In addition to cooling oil, an air aftercooler is used to cool the discharged air and to remove excess moisture. In most applications, radiator type coolers (figure 4) are used to provide heat recovery from the compression process and use it for facility heating. Water cooled heat exchangers, are also available on most rotary screw compressors. When we raise the pressure of the air, the temperature increases and therefore so does the entropy of the fluid. The entropy is a measure of energy loss. A real compressor requires more work to raise the pressure of the air to the same outlet pressure than a theoretical compressor.

7 Orgad air compressors אורגד מדחסי אוויר

8 פי.סי חץ

9 אבגור – אביזרים בע”מ

Referred to generally as a twin screw compressor each rotor comprises of a set of helical lobes affixed to a shaft One rotor is called the male rotor and the other rotor is the female rotor. The number of lobes on the male rotor, and the number of flutes on the female, will vary from one compressor manufacturer to another. However, the female rotor will always have numerically more valleys (flutes) than the male rotor lobes for better efficiency. Male lobe acts like a continuous piston rolling down female flute which acts like a cylinder trapping air and reducing space continuously.

10 מיזוג אוויר

The temperature of the oil injected into the compression chamber is generally controlled between 60-700C. The discharge temperature must remain above the pressure dew point to avoid condensation of moisture that would mix with the oil. A thermostatic valve controls the quantity of the oil being circulated to the oil cooler or to the bypass in order to maintain the desired temperature over a wide range of ambient temperatures. A mixture of compressed air and oil leaves the air end and is passed to a separator where most of the oil is removed from the compressed air using directional and velocity changes. Then coalescent filters are used to remove the remaining oil resulting in very low oil carry over (usually 2-5 ppm)

By Coco

By Coco